Enhanced Fretting Fatigue Resistance of Conductors for High Voltage Overhead Lines (CONFAT)

While overhead-line electricity transmission grids are generally well established in Europe, and there is not a big incentive to install new or replace existing conductors, there is an interest in improving reliability and maximising current flow with minimum impact on operating lifetime. This is the focus of the CONFAT project.

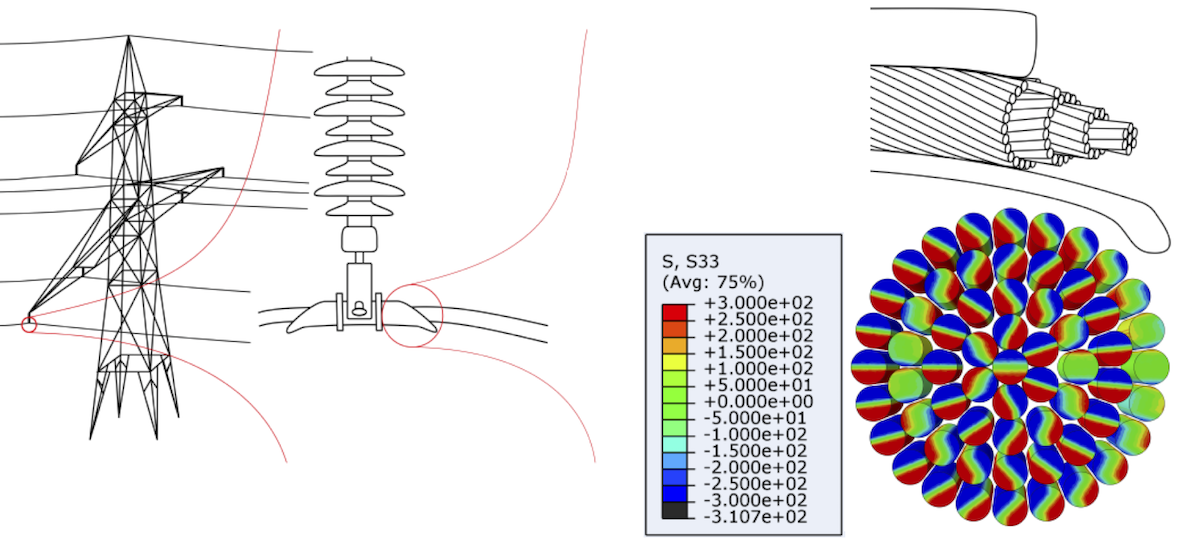

Typically, a 30mm diameter E-AlMgSi conductor comprises ~60 individual ~3mm diameter wires counter-wound in 4 rows about a central core by a stranding process intentionally responsible for a complex internal residual stress distribution to maintain form during service duty. One cause of conductor failure can be the consequence of Aeolian vibration and fatigue due to fretting between wires in the outer and penultimate layers at locations close to suspension clamps.

The risk of fretting fatigue crack initiation may be minimised by reducing the magnitude of internal mean stresses in the conductor wires resulting from the manufacturing process. Since the aluminium alloy both ages and creeps at relatively low temperatures, it is conceivable for this goal to be achieved by a local thermal treatment in the field.

The CONFAT project is assessing the feasibility of this practical solution: by characterising the ageing and creep response of E-AlMgSi in laboratory tests; by simulating the effect of thermal treatment on residual manufacturing and service induced bending stresses; by elastic-plastic-creep FE numerical simulations; by the direct measurement of internal stress state by x-ray synchrotron; and by determining fretting fatigue resistance in individual wire and full-size whole conductor benchmark tests.

The CONFAT project involves a research collaboration between PFISTERER SEFAG AG and the ESC member Prof. Dr. Edoardo Mazza. The work is being conducted by the external pageHigh Temperature Integrity Groupcall_made which is part of his Laboratory for external pageMechanical Integrity of Energy Systems at Empacall_made. The Group develops new high temperature mechanical assessment procedures, primarily for energy systems, and verifies their effectiveness by service-like benchmark testing complemented by metallurgical condition assessment. In this thematic area, the Group cooperates with the High Voltage Laboratory of ETHZ (Prof. Dr. Ch. Franck) and Swisselectric Research.