Radical innovation for low energy concrete structures

“Low Energy Concrete”, a project supported by SNF, has been set-up to look into the improvement potential of building materials by developing low-energy construction products. A new generation of Portland cement with clinker substitution up to 65% has been defined, able to decrease up to 60% the energy needed for manufacturing.

In Switzerland, about 40% of the total energy consumption comes from the building sector. In the last decades, many efforts have been made to increase the buildings energy efficiency. However, the continuous reduction of energy consumption during operation underlines the increasing contribution from building materials.

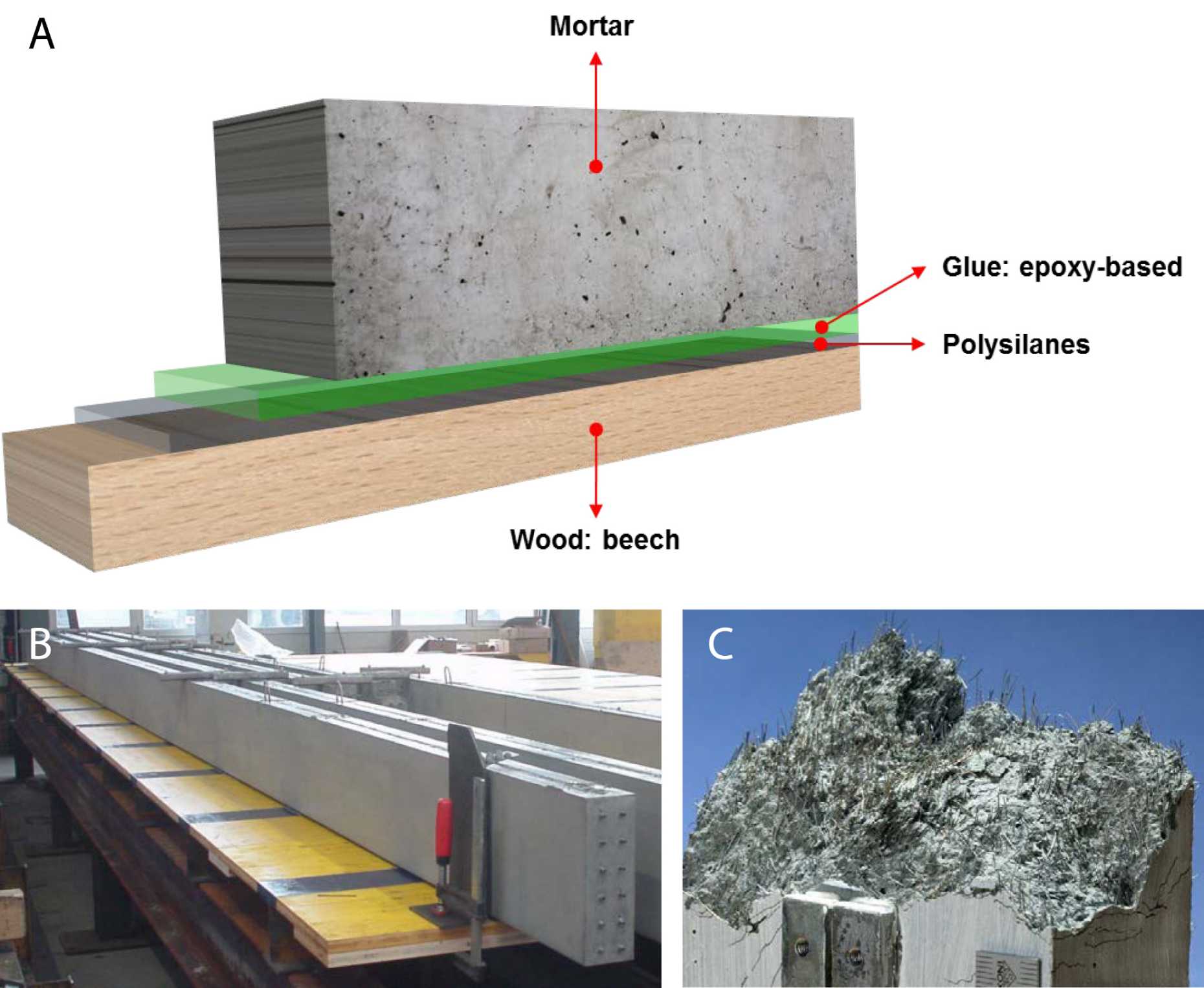

The current project involving ETH, EPFL and EMPA teams, developed a new low-clinker cement made with addition of limestone and burnt oil shale in cement, together with compatible superplasticizers. Optimization in concrete is the base for development at structural level, focusing on technologies that combine low energy concrete with tensile-resistant materials other than steel in order to achieve high durability targets with low amount of cement protection. One possibility is to combine the innovative concrete with beech-laminated panels to create hybrid structures, but other special pre-cast applications are targeted with the use of carbon fibres instead of steel reinforcement in high performance concrete elements. Carbon fibres are attractive alternative as they are strong and more corrosive-resistant than steel. The steel fibres can be also replaced with synthetic fibres such as basalt and polyethylene, which require less energy for production. The ultra-high performance concrete is a promising alternative in applications when high durability properties are required.

Professor Guillaume Habert leads the chair of sustainable construction at ETH Zurich and wants to promote the appropriate application of construction materials during the entire life cycle of buildings and infrastructure. This involves an interdisciplinary research group being able to analyze a context from the material to the urban scale involving expertise from material science to life cycle assessment and Material flow analysis.

Guillaume Habert studied biology and geology and graduated with a degree in earth, atmospheric and oceanic studies and specialized in structural geology. He then used his knowledge of natural rocks mineralogy to explore how specific clays and pozzolans can be used as a cement substitute. His work focused on the development of sustainable concrete. This also led him to address the environmental evaluation of building materials as well as the development of new binders such as geopolymers. He is teaching Sustainable construction at ETH since 2012. The research project described can be viewed external pageherecall_made.