Energy Harvesting for Next Generation Freight Trains

Remote sensors and actuators are gaining in importance for the Internet of Things (IoT) and energy harvesting could power these systems directly at the location of consumption. In distributed systems or in harsh environments, e.g. sensors/actuators on a freight train car, this allows improving reliability and efficiency, while decreasing costs.

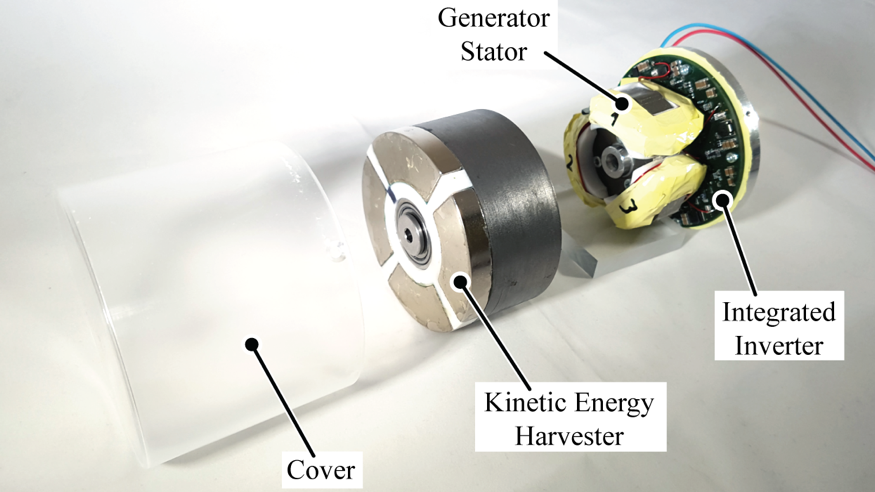

Wagons of freight trains typically do not have an on-board electric power supply and therefore, sensor and actuation electronics, e.g. for monitoring of the wagon condition or for supplying an anti-lock braking system cannot be installed. In this research project, concepts for harvesting energy from moving conductive surfaces are investigated and an energy harvester, which can harvest electric power from the freight train’s wheel, is developed.

The research project is carried out at the Power Electronic Systems Laboratory, D-ITET, in cooperation with external pageNabtescocall_made (Japan), a world leading mechatronic systems manufacturer and targets the conceptualization and optimization of novel concepts for energy harvesting from moving conductive surfaces. An example application is the power supply of sensors or actuators on next generation wagons of freight trains. Currently, they do not have on-board electric power supply and accordingly, cannot employ electronics, e.g. for monitoring the wagon condition or the conditions of transported goods. Another application is the supply of a future anti-lock braking system on freight wagons. With the energy harvester and related power electronics developed in the course of this research project, this deficiency can be overcome and new monitoring and sensing concepts are enabled in a wide range of industrial applications. The depicted energy harvester allows to harvest up to 7.5W of electric power from the moving freight train’s wheel over an air gap of 10mm.

The persons involved in this project are Michael Flankl, and ESC member Prof. Johann W. Kolar.

For more information about this project, please visit the project website.

Prof. Kolar is head of the Power Electronic Systems Laboratory (PES). The research at PES opens up new fields of applications and drives the innovation of power electronics systems in close partnership with both Swiss and international industry. In line with the focus areas of ETH Zurich, fundamentally new concepts, e.g., for sustainable energy systems, sustainable mobility, future datacenters, and medical applications, are of primary interest, along with general scientific challenges and the pursuit of excellence and an internationally leading reputation.