A New Player in Grid-Level Stationary Energy Storage – Efficient and Low Cost Aluminum Chloride-Natural Graphite Battery

A new rechargeable aluminum chloride-graphite battery was designed using processed natural graphite flakes in its cathode. The major performance metrics – energy density (up to 62 Wh kg-1), power density (500-1000 W kg-1), energy efficiency (90%) and long cycling life (>5000 cycles without capacity loss) – are ideal for grid-level stationary energy storage.

The future success of renewable but intermittent energy sources such as solar and wind will largely depend on the availability of low-cost, TWh-level stationary storage systems. Furthermore, there is a pressing need to locally and globally stabilize and diversify the electric grid. Large stationary installed batteries are expected to play the major role in this regard, in addition to conventional storage means such as pumped hydro. For ensuring their long-term sustainability, electrochemical storage technologies shall exclusively comprise highly abundant chemical elements.

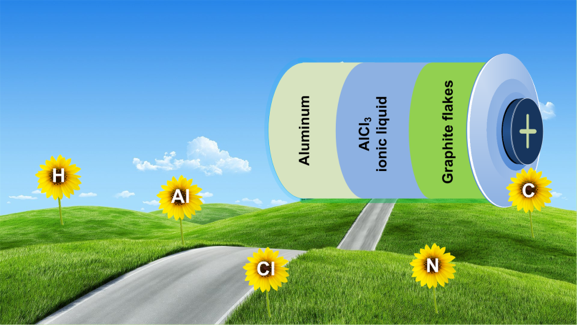

In the search for an ultimate cost-effectiveness, the group of Prof. Maksym Kovalenko (D-CHAB) has developed efficient and low cost aluminium chloride-graphite battery consisting of an aluminum foil, AlCl3-based ionic liquid and natural graphite flakes of ca. 50 µm in lateral size. These flakes can be easily manufactured from typical natural graphite ore rocks by means of crushing, floatation and chemical purification (standard industrial processes), combined with secondary processing for reducing the flake size (sonication, ball-milling etc.). The retention of flaky morphology upon fragmentation without folding of the edges had been identified as key factor for high electrochemical performance of aluminum chloride-graphite battery.

The people involved in this project are ESC member, Prof. Maksym Kovalenko, and Dr. Kostiantyn Kravchyk.The external pagefull articlecall_made about this project can be found on ACS publications.

Prof. Kovalenko is head of the Functional Inorganic Materials Group that focused on challenges related to the chemistry, physics and applications of inorganic nanostructures.